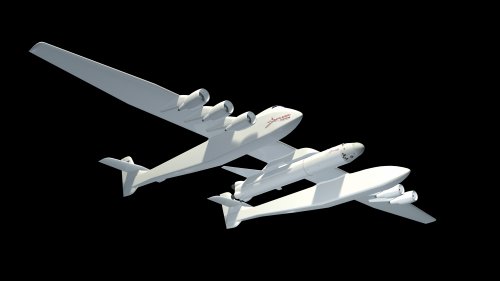

Tuesday’s announcement of the plans by startup Stratolaunch Systems to develop an air launch system attracted considerable attention and excitement, and understandably so. The world’s biggest airplane! A “dream team” that reunited Paul Allen and Burt Rutan for the first time since SpaceShipOne! An industry team that includes Scaled Composites and SpaceX! A board that includes not just Rutan and SpaceX president Gwynne Shotwell, but also former NASA administrator Mike Griffin! And did I mention the world’s biggest airplane?

However, the more I thought about it later Tuesday and into yesterday, the more questions developed in my mind about this venture. From a technical standpoint, I don’t doubt that the Stratolaunch team has the ability to develop what they’re proposing, particularly given the experience of Scaled and SpaceX. Yes, there will be complications along the way, but these companies are as well positioned as any to deal with them.

Instead, I’ve been pondering this question: what problem does this system solve? That’s the key question for any business venture, not just a launch vehicle company. What can Stratolaunch do that others can’t do, or do as well or as cheaply? Air launch has its advantages, but also carries with it some disadvantages and other issues. That, coupled with what the company has released about its technical capabilities, leads me to wonder if the Stratolaunch system will really be that competitive over more conventional launch systems in service or under active development today.

Here are a few issues to consider:

Big plane, bigger pricetag. It’s likely the single most expensive element of the Stratolaunch system will be the aircraft. The rocket will be derived from the Falcon 9, with only four or five engines and a shorter first stage (perhaps equipped with some kind of delta wing, like on the Pegasus, according to the animation), which will reduce its development costs compared to a clean-sheet design. Developing the plane the size of what they’re planning will likely cost much more, even with their plans make use of existing 747 components, from the landing gear to its jet engines.

How expensive? The company hasn’t disclosed its development costs, beyond a statement by Paul Allen at Tuesday’s press conference where he said he expected to spent “an order of magnitude more” on this than he did on SpaceShipOne. Given that he spent $28 million on SS1, according to his memoir published earlier this year, that suggests spending around $300 million or more on Stratolaunch. And that may be still too low, as $300 million is in the ballpark for what it has cost to develop WhiteKnightTwo and SpaceShipTwo, a much smaller carrier aircraft and suborbital vehicle, respectively.

The Stratolaunch aircraft will be on a scale similar to the largest jetliners, like the 787 and A380, whose development each cost over $10 billion. Of course, those are passenger jetliners with significant certification costs, as well as upfront costs for construction of potentially thousands of such planes, while only one or two Stratolaunch planes, not intended (presumably) for passenger service, might ever be built.

The Airframe Cost Model provides an extremely basic cost model for aircraft development based on empty weight and speed. Those details aren’t available for this plane (only the gross takeoff weight, 1.2 million pounds or 540,000 kilograms, is given), but assuming a modest empty weight of 250,000 pounds—about the same as the considerably smaller 787—and a top speed of 300 knots, the model yields, for one test aircraft and one production model, a total cost of $4.7 billion (in 2004 dollars). That is almost certainly far too high: the model is based on the production of older military aircraft, including the giant C-5 cargo plane, and Scaled is likely more efficient and able to make use of more advanced technologies to reduce costs. The question, though, is the model is off by a factor of ten, or only a factor of five or less?

How flexible is air launch? One of the advantages touted by air launch proponents is the flexibility to launch from a wide range of locations. You don’t need the fixed infrastructure of a launch pad; instead, just take off from your desired airport, point the plane in the right direction, and fire off the rocket. No worries about coordinating range availability with other rockets or maintaining expensive launch pad equipment. Orbital Sciences Corporation’s Pegasus, the most successful orbital air launch system, has demonstrated that flexibility by flying from several airports from the US and overseas.

However, the sheer size of Stratolaunch—far larger than Pegasus, which uses a converted L-1011 jumbo jet—will limit that flexibility. The aircraft requires a 12,000-foot (3,650-meter) runway, sharply limiting the number of airports in the US or elsewhere it can take off from. In addition, unless the first stage is reusable and designed to fly back (which it does not appear to be from the animation), the launch will have to take place over open water or very remote unpopulated areas, further limiting the airports to those in range of those drop zones. It’s no wonder, then, that the press release identified Kennedy Space Center as one possible launch site, given its five-kilometer-long Shuttle Landing Facility runway and access to the Eastern Range.

Moreover, any airport that Stratolaunch operates from will need some infrastructure that may be unique to that system. That will include a hangar large enough to accommodate the plane’s 385-foot (117-meter) wingspan, as well as propellant storage (RP-1 and LOX for the rocket) and equipment to integrate the payload onto the launch vehicle, and the launch vehicle onto the aircraft. That suggests that the plane will likely operate from only a handful of sites unless the company can find a way to scale back those equipment requirements.

A limited market. Stratolaunch advertises that the rocket can place up to 13,500 pounds (6,100 kilograms) into orbit. The specific orbit isn’t mentioned, but it’s most likely a favorable low-inclination due-east orbit, with decreased capacities for polar and sun-synchronous orbits as well as geosynchronous orbit. That makes it comparable to the Delta 2 Heavy, the most powerful versions of that vehicle that is on the verge of retirement. While Allen and others at Tuesday’s press conference brought up the idea of eventually flying crewed spacecraft, initially their focus is on launching satellites.

The problem is that this may well be a limited market. “There is a thriving communications satellite market for small to medium-class communications satellites,” Mike Griffin said at the press conference. However, a vehicle with this stated LEO capacity can likely carry satellites weighing no more than about 2 tons to GEO; the communications satellite market today is dominated by much larger satellites, with virtually nothing that small being built today. See, for example, the FAA Commercial Space Transportation Forecasts report for more data, in particular Figure 5 and Table 5, which shows only about 1 commercial GEO satellite a year with a mass less than 2,500 kilograms projected for launch through 2020.

A more likely market is for civil and military government satellites, of which Griffin estimates that there are about a half-dozen a year that previously flew on Delta 2. However, by the time Stratolaunch enters service, no earlier than 2016, Orbital’s Antares (née Taurus 2) rocket will have been in service for some time, serving that market; even SpaceX’s Falcon 9, while more capable, may attract customers with such satellites at its currently-advertised launch costs. There are also international options for non-US Government customers, like the Soyuz (now launching from French Guiana in addition to Russia and Kazakhstan), Land Launch’s Zenit-3SLB, and the Angara that is still under development in Russia.

It may turn out that Stratolaunch can beat out those other vehicles on price when it is introduced. (Company officials haven’t disclosed a target launch price for the vehicle.) However, given the inelastic nature of many of these existing markets, a lower-priced alternative may not stimulate much, if any, additional demand. This would force Stratolaunch to compete head-to-head with other companies (including potentially SpaceX) for the limited number of launch opportunities in this portion of the market.

This analysis is incomplete, primarily because it’s based on the limited technical and business information provided by Stratolaunch so far—a luxury it has thanks to the financial backing of Allen. There may be missing pieces to its business plan that make this system far less expensive to develop and operate and far more competitive in the global launch market than this analysis suggests, particularly if it can move into human spaceflight markets. Otherwise, despite being an interesting technical concept backed by an impressive team, Stratolaunch may not be that compelling in the long run.

I agree with the overall assessment. What has me intrigued, however, is that there are so many heavy hitters involved. Certainly, major companies lead by industry-leading visionaries have put out flops in the past. And by no means do I think Allen/Rutan/Shotwell/Musk are incapable of failure, even spectacular failure. But SpaceX’s successful navigation of their respective markets and Allen’s demonstrable buisiness acumen suggests that there’s some business case to be had that isn’t immediately apparent.

Also, to the flyback comment, I think we’ll see flyback on the rocket 1st stage and possibly the second and/or capsule. The video didn’t show flyback, but Allen noted SpaceX’ reusability plan as a major cost advantage in this partnership.

I’m thinking SpaceX is playing synergies here. With Grasshopper slated for upcoming flights, a reusable F9 announced to much fanfare, and now this project with a noted reuse component, I think we’re seeing a core development track toward multiple end products. That’s how they’ve done things so far, as well, with most components of F1 feeding into F9, which then evolves into F Heavy, with each component being a functional product that continues on past development. I suspect Grasshopper will likely live on as a sounding rocket in the future as well, though SpaceX has stated outright that sounding missions are not the primary goal of it.

Good article Jeff, though I still think it’s too early for skepticism. But I do more or less agree with what you mentioned in your tweet to me, that critical thought shouldn’t have a waiting period. Still, it’s hard to think critically when the information available is so much awash with speculation.

Quick question/remark: when Stratolaunch say they can launch from multiple locations, isn’t that referring to the many locations within range of their base, i.e. I’m not sure they meant many take-off locations for their carrier aircraft.

Also, isn’t another benefit of air launch the ability to have longer launch windows? For example, to launch to the ISS you have to time your launch to the arrival of the ISS orbit over your location, whereas with air launch you can move east or west and position yourself for multiple ISS orbit passes. Or have I got that wrong (my orbital mechanics is quite basic).

Cheers!

A well-considered analysis, Jeff, and good points made throughout. One of the first thoughts that occurred to me when I heard the announcement is how well this fits Burt’s joy at tackling aviation engineering challenges, and his propensity to chastise the aerospace industry for putting profit before technical advances.

As you point out, it will be interesting to see how these converge with Stratolaunch.

Sorry to say, but I had the same reaction. The business plan for this seems to have some severe built-in contradictions.

It is obvious predicated on the availability and viability of the Falcon rocket series. Very well, I buy that; SpaceX seems to know what they’re doing. Anyhow, you certainly can’t say that this venture is viable and simultaneously say that SpaceX is bunk.

If the SpaceX is viable, then the Falcon 9 is viable. And it can launch a lot more payload than this. If you don’t need to launch that much payload — well, then, there’s nothing stopping you from launching a half-empty Falcon 9, right?

So, let’s compare the costs of a Falcon 9 vs. a Stratolaunched Falcon 5. (Assume that the amortisation costs of both rockets are the same, and cancel each other out.) On the one side, you have range ops, a slightly larger tank, an 4 extra Merlins. On the other side you have the ops and amortisation costs for the largest aircraft in history. While I can only guess at the numbers on both sides of that equation, I’m unable to construct a plausible scenario which works in Stratolaunch’s favor. Maybe if Merlins were as expensive as hand-built SSMEs, rather than being cheaply mass-produced on an assembly-line… but then in that case, neither rocket would be at all competitive with other options already on the market, so that doesn’t work either. In reality, there’s just no way that the marginal cost of four Merlins could be even a fraction as much as the amortisation costs of that aircraft.

Okay, so maybe cost isn’t the issue; launch-site flexibility is. Maybe it’s SO important that it’s worth paying a premium for. Obviously launch-site flexibility will incur some major development costs, but consider this: the reusable “Grasshopper” stage that SpaceX is already developing will actually offer FAR greater launch-site flexibility than the Stratolifter does, since it eliminates the need for a 12,000-foot runway or a range where you drop spent stages. does anybody think that the cost to develop that will be significantly greater than the cost of developing the Largest Aircraft Ever Built? (Not to mention that it gets you reusability for free…).

In short: if SpaceX fails, then this fails. But if SpaceX succeeds, then this fails. The math for Stratolifter is so far from adding up that it’s just baffling. I respect a lot of the players involved, and hope that they are seeing something that I’m simply overlooking… but after 48 hours of pondering, I haven’t figured it out yet.

[…] Foust has a contrarian view. I think a key issue, and a source of a lot of the cost uncertainty, is regulatory. If they have to […]

Stargazer is certified by AVR, and I think it operates under Part 127, even though it doesn’t carry any passengers. How much will this increase the development and operational costs of Birdzilla? On the other hand, maybe it will find other markets than just as a launch platform.

I wonder if an all-new airframe would really be that much cheaper than taking an existing aircraft and adapting it?

By coincidence, DARPA and NASA have recently assessed this…

http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20110015353_2011016245.pdf

…and conclude (see Summary on p.68) that an adapted 747 could launch up to 15000lb and that “…a useful flight demonstration is possible within a funding profile of less than $350 million over four years”. This also aligns well with similar studies that have been performed over the last 25 years (e.g. the Teledyne Brown concept from Dan DeLong and Ernst Stuhlinger from 1986 in AAS 86-463) and so raises the question of just how much of an advantage a new airframe provides.

Of course, the really big step to lowering launch cost — and the really big challenge — would come from a fully reusable rocket stage, so maybe this new airframe is really aimed at that ‘next step’?

Cheap access relies on reusability and low launch preparation costs. SpaceX is already working hard on the latter, trying to reduce the number of people and time spent on preparing the rocket, targeting roll out, fuel, and launch in an hour. I can’t see the costs for a short F4/5 being much different especially after adding in the preparation of the aircraft.

So it comes down to reusability. If the SpaceX’s Grasshopper-based system doesn’t pan out, then Stratolaunch with a reusable first stage will provide a much lower cost but if SpaceX does manage to reliably recover their first stage, I don’t see how this will offer much of an advantage.

A good summary of what we don’t know. I kept waiting for the other shoe to drop and something significant to be announced at the press conference, but didn’t hear it either.

However I did hear Burt talking about why they decided to come out about the program now (I forget why it was), and it could be that we’re only seeing just the bare bones of what they plan. It could be they are setting expectations low so they can experiment with their higher payoff services. Maybe not, but I certainly hope so.

If I was a really suspicious person, I would think that this was a cover for a DoD program, ala what Howard Hughes did with the Global Explorer. Stick the X-37B on the front of that booster instead of the Dragon lookalike, and now the Air Force has a truly flexible space vehicle platform. Maybe the Air Force has guaranteed use if they build it? Oh, but that’s if I were a really suspicious person…

From the legal perspective, if they use the 747 design and components instead of a clean-sheet design, I wonder how this design will impact Boeing’s intellectual property rights specifically in regards to patents on the 747 and its components. Surely as this would be an unwelcome competitor to Boeing’s family of Delta launchers and ULA in general, Boeing might attempt preemptive litigation aimed at preventing the modification of the 747 airframes for this venture.

747 first flight? 1969.

Public viewing? 1965?

45 years later the patents are mostly shot.

Which may explain why they don’t use a 777 or a380

Jeff-

I am not a aeronautical engineer; just bringing up a few points for your (re)consideration.

1. An aircraft manufacturer develops a new airframe every decade-ish. The exorbitant cost is a function of innovating the entire aircraft; down to the minute detail, including the processes to manufacture and support the entire system. But they do bring out new “products†quite often. By focusing on a business need or problem and only developing what is required, the “development cost” is a fraction of designing the end-to-end system.

For the carrier craft, they are only “developing†the airframe (paraphrasing Mr. Rutan); using the technology that led to building large scale airframe components at a fraction of the cost of traditional methods. His carbon fiber construction techniques have allowed him to design and built a vast array of aircraft and even a few automobiles; often with a “production run†of only 1 or a few. White Knight 2 has only 2 orders and Space Ship 2 only 6. “Development” costs are now easily absorbed in extremely short-run production. Where we say quick prototyping, he says R&D&Manufacture. Wow – do we really get how much that changes the game? Burt hopes not, it would be a drag for him to start having competition.

2. Elon has much to gain:

A. “Falcon 4 or 5″ loses half the engines in the first stage and the resulting propellant mass required JUST TO LIFT THE OTHER ENGINES (frustrating rocket engineers since day 1). You do not gain payload mass by a factor of the power of the engines, so every engine and resulting mass he sheds, he gains in heavier or cheaper payloads (per pound) to space, and that is what everyone is trying to figure out how to do. So far, a 10% improvement in efficiency is worth building a brand new rocket; this could give him more, and no “new†rocket development costs…

B. Following Garrett’s comment, you only need 1 runway (US has at least 2 commercial and 1 military: Kennedy, Spaceport America and Edwards …) and you gain any “launch site†you require within 1300 nm. Elon now has more orders than he can launch on fixed pads in CA and FL, and is currently looking for another. This solves his problem in a big way while re-using existing processing facilities if they use the Cape, or the rumors he is SpacePort America may not be for a fixed pad (hmmm…).

3. The Rutan factor: He may seem a little quirky, but he does not talk about building ANYTHING until he is pretty darn sure he can do it, and then he does it! In this case it is the engineers already building a smaller scale of the same aircraft, he just agrees with their analysis!

Sorry, I meant Dave!

Er, whoever wrote the article ;-p

Jeff,

I think you have identified a mystery, but I attempt to solve it:

1. The plane will be able to carry what the AN-225 can carry assuming it’s in an airframe shaped container and some stuff like rockets that don’t need one. It will also be able to test components that are too big for White Knight 2 to test, so the plane will likely be break even if the rocket never flies.

2. Scaled and SpaceX a history of delivering on budget and with the composite baked in house and the Rocket from SpaceX, it’s not unreasonable for the price to be a factor of 10 lower than Airbus. There are no political constituencies that are clamoring for pieces to be manufactured here or there and there is no need to shop for vendor investment.

3. This is clearly SpaceShipThree and WhiteKnightThree. I’m heartened their going with liquid fuel this time. I think this is passenger launch to ISS/Bigelow perhaps with a Dragon capsule. The Dragon wet mass is 4400kg http://www.flightglobal.com/news/articles/picture-spacex-reveals-first-dragon-engineering-unit-212634/ permitting some people to ISS or Bigelow at a lower price point than Falcon 9’s $12m/head. Hopefully they’ll find a Richard Branson or similar to commercialize, popularize and operate it.

StratoLaunch is perfect for launching the Boeing X-37 which is also built in Mojave at Edwards AFB, and was dropped by White Knight one. It will be cheaper per launch for X-37 than a $200-Million to $400-Million Atlas V launch vehicle.

The StratoLaunch aircraft should cost $500 Million or $1,000 per pound of payload lifted. This is what White Knight One and White Knight Two cost at $8 million and $50-Million respectively.

The Falcon-4 booster from SpaceX will be single-stage to orbit (SSTO) if you calculate its performance with 4 Merlin 1-d vacuum engines (at 335 sec Isp) to lift 13,200-lbs to orbit after air drop at 30,000 feet. They do not need a second stage as seen in the promotion video. If they use the new SpaceX LOX/Methane staged combustion engines with 385-second vacuum Isp, then payload performance may double.

You make the point I think we should examine closely. The stated 5-10% rocket performance improvement over ground launch is exactly what is needed for a single rocket stage. Given a higher performance engine, and the flexibility of launch point, reusability becomes a real possibility. The single rocket stage would be a once-around stage with the launch point tailored to drop it on the landing area, minimizing extra prop. Reuseability – landing a rocket – also brings up safety concerns. Given reentry profile over the Gulf, safety concerns are minimized. So Florida is the perfect site for a reuseable system. Going forward, the stated facts seem to point to a growth capability to a fully reuseable system. The basic point is to use the extra performance not to increase “paying” payload, but increase reliability and reuse.

What sort of applications do you imagine are there for a flexible, on-time, fully reuseable (i.e, reliable and low cost) system to take the stated weight to LEO? People seem to be included as the ultimate cargo of this system, if they can actually pull these things off. Sort of like the SpaceX approach, with evolutionary improvements leading to bigger and better things.

BTW, the cost of the launch aircraft – and eventually the rocket (hopefully) – would be amortized over many launches. I would expect the cost per pound would be much lower, even with maintenance costs, given the expected operational life of an aircraft is measured in years if not decades.

I think the must useful thing about this would be to launch the rocket with a shorter 1st stage, west of califronia and then have it use the grasshopper technology to land the 1st stage on the coast somewhere. This way the 1st stage does not have to fly over any populated area. Or maybe the aircraft will have some method to catch the 1st stage in air? heh

This looks like a much larger version of Len Cormier’s air launch system. He focused on small winged orbital vehicles (manned) that could carry a few hundred to several thousand pounds to orbit. He went through numerous design iterations, the latest of which was called the Space Van, an air launched vehicle that had dual fuel (kerosene, hydrogen) and oxygen engines. The whole system was to be reusable.

To avoid development costs for his larger vehicle designs he was always looking for a large aircraft to modify to carry his vehicle to 35,000+ feet. A bonus feature would be a rocket engine on the carrier aircraft to boost both vehicles to ~100,000 feet for release, giving a larger payload to orbit. I believe his last design was to use a modified large Russian turboprop cargo aircraft.

Anyway I believe Burt Rutan has certainly heard of Cormier’s work and that Phase II of the Stratolaunch project may just involve a large dual fueled orbital Space Ship Three….

It might be easier to start with the existing 747 fuselage, or the C-5 with its high wings and T-tail. NASA has studied “twinned” 747’s and C-5’s before, and there would be significant infrastructure costs. The aircraft would need a runway over 200 feet wide. Runway 12/30 at Scaled Composites’ home in Mojave is 12,000 feet long and 200 feet wide, but only rated for up to 120,000 pounds. A new runway could easily cost a billion dollars, and you would need one every place this big bird would land.

Since the 747-8 has payload capacity of 135,000 pounds, someone should consider that as a launch aircraft. It will not be the first time a 747 has launched a Space Shuttle!

Louise, stock 747’s start at 358,000 lbs empty, and since the Mojave airport is also the one they use for the storage field, I’m sure it’s rated for more weight than that. Maybe you were confusing kg with lb?

Anom, we won’t be able to take the cost of the carrier aircraft and divide it into the payload weight to find the $/lb to orbit, since the aircraft is reusable. The SpaceX rocket portion would count towards the $/lb as long as it’s non-reusable, but I would imagine reusability of both the 1st & 2nd stages is high on their list of things to do, so we’ll see.

[…] rockets from a huge airplane (newspacejournal.com provides an interesting technical and economic analysis of the […]

Just because it is large doesn’t necessarily mean it is limited in launch sites. As long as it can land, refuel, and take off again, hanger and specialized equipment can be at one or two locations. 747 equipment is designed for many duty cycles. Perhaps more limiting is where the payload (i.e., rocket and rocket payload) is readied.

The primary flexibility advantages – no range scheduling, weather avoidance, launch to various inclinations – means a long runway near an ocean. But they have that.

There are many 12,000 foot runways in the United States.

Pretty much every retired SAC base has one, such as Bergstrom Airport in Austin Texas, as well as the large air carrier airports that serve international flying.

If an A380 can use the airport then so could a Stratolaunch.

This proposed airplane is big, but it’s mostly going to be hollow. At most only the crew cabin will be pressurized, perhaps not even that. It will have nothing like the complexity of a commercial airliner, so cost models for commercial or military aircraft will overstate the cost for a Rutan type design.

[…] of the first industry analysts to question it, and issue a contrarian view, was Jeff Foust, over at the NewSpace Journal. He notes that the projected costs for the aircraft are far lower […]

I wouldn’t put too much weight into the “order of magnitude” remark. That’s a pretty imprecise statement and likely isn’t a hard limit. For Paul Allen, $500 million is almost petty cash. Not having to finance the project will save a lot of money in the long run.

We have to be careful about depending too heavily on traditional cost models. Most are based on business as usual cost-plus development efforts and have not proven very accurate. Cost and schedule overruns abound in the cost-plus world because there is no incentive at controlling costs. Projects built on a non-cost-plus basis can come in significantly cheapter. For example, according to NASA, SpaceX spent approximately $300 million to develop the Falcon 9. Using NASA’s traditional development methods, it would’ve cost at least 10 times as much. NASA itself as admitted as much and their history shows their cost estimates are almost always too low.

Aviation Week is reporting that the company is looking to buy two used 747s to salvage for usable parts. There just happens to be a lot of old airliners including 747s parked at Mojave airport. They plan on salvaging the engines, landing gear, cockpit and other usable components. Used engines are perfectly acceptable for a plane that isn’t going to fly very much and will save many million dollars over new engines. Landing gear development is challenging and expensive so reusing 747 components will save a lot of money and time. Scaled Composites has decades of experience at building special purpose aircraft at far less cost than traditional companies. That’s why the company exists. Northrup-Grumman bought Scaled to obtain a highly capable “Skunk Works” of their own and have used the company to good effect.

Good points Jeff, I started with Rands article making it to yours. In revisiting the X-37 I found this photo today, which was news for me of the “The X-37A’s carrier aircraft for atmospheric drop tests is the Scaled Composites “White Knight” aircraft (carrier of the “SpaceShip One” X-Prize vehicle). ” http://www.designation-systems.net/dusrm/app4/x-37.html

These guys are not kidding around. They are definitely on to something and are definitely under playing the expectations and not revealing all their options

Here is my speculation on what they may be considering:

1. Stratolaunch carrier aircraft can be used to ferry SpaceX launchers around – plain old vanilla logistics.

2. Use the carrier aircraft for massive lift operations when it is not being used for launches – exotic logistics – they have stated this explicitly

3. With this as a proven launch system, they can take the launch to the customer site and their payload and not ship the customer and their payload to the launch site. I wonder what sort of customer would find that attractive and why.

4. Alliance with Boeing – use of its airplane tech and parts and expertise – also dovetails with the potential to launch Boeing’s X-37B/X40 derivatives or any other “space plane†as the final stage

5. They may be shooting for recovering and reusing the 1st stage of the SpaceX rocket – which itself could be a 2 stage + final Dragon capsule/X-37B like space plane. Or more ambitiously a single fully recoverable stage plus the final space craft/reentry vehicle/lander stage

6. In the first phase they could go the proven conventional route and make the recoverable SpaceX rocket first stage (or the entire thing) splash down into the ocean to be recovered by ships.

I know this is outlandish. Hey I am just a dreaming amateur.

7. Maybe they are dreaming of capturing the SpaceX rocket on its way down (using multiple humongous parasails and maneuvering thrusters) using the same Stratolaunch carrier aircraft that launched it in the first place. That will be cool. 100% reusable, no ocean splashdown and you also have the holly molly Horizontal takeoff and horizontal landing starting and ending from the same location. It would be safe flexible as all the launch and recovery could be done over oceans and international waters fast turnaround as well as use excess capacity in for other more mundane logistical operations